|

Life's been hectic. The country is in shambles, and words can hardly describe the different emotions flying around. But we've remained committed to the project at hand, and have moved forward in the prototyping stages. Team members JD and Stephen will add the final project changes/prototype iterations to El Gran Papiazo, as well as attempt to create a 3D assembly of the tensile roof in Solidworks. This will be a 'finishing' round of documentation, and will complete the hand off the team will give to the next rotation. Moving on to the meat of this update, team members Jose and Natalie have come along nicely with different prototypes of their assigned parts. The former is struggling a bit to create his wooden/fast prototype, since, in his esteemed words "Home Depot never pulled through." With household items, he was able to create the edge of the cuff, pictured below. Still passable, given the circumstance. Natalie had a little more luck, as her 3D printed part came in the mail. She was able to fit the whole cuff into a random tree in her backyard, and it sits on there nicely. The geometry works out, and the only issue is that the initial grommet position was not correct. We will be moving to fix that shortly. With the prototypes nicely made, we are finishing up everything else, gearing up to turn it all in. Good luck to everyone else!

- Structures Team

0 Comments

Like last week, the Structures team is in the process of making a transition from the documentation phase -- during which we wrote the Gran Papiazo (EGP) -- to the final phase of our revised spring quarter plan: prototyping. While we have compiled a list of necessary materials in this preliminary materials list and delegated specific orders to members of the team, we are still waiting on a number of orders to arrive. In addition, COVID-19 has made it harder to get access to certain materials that we would normally be easy to find. For example, Jose made two trips to separate Home Depots but was unable to find the wood board necessary to construct an initial prototype of our slanted roof design (details available on pp. 12 of EGP). We did have some success, however, with grommets and finding a new vendor to 3-D print our cuffs (design sketches available on pp. 13 of EGP). Natalie was able to use the General Tools Brass Grommet kit to create a grommet in the corner of the canvas we ordered from Amazon. As noted last week, the original 3D printing vendor we had planned to use turned out not to deliver until late June -- too late to be useful. We were able, however, to identify a new 3D printing vendor this week with the help of Professor Debbie Senesky (AA). We will now be placing an order for a 3D-printed cuff through You3DIt Inc, which will hopefully be delivered in the next week or so.

This coming week, we are hoping that Jose will be able to the wood board he needs to begin constructing the roof. Once Natalie and Jose have constructed their various prototypes, they plan on passing photos on to JD and Stephen who will create documentation regarding the prototypes to aid next year's team, integrating that documentation into EGP. As a final note, we are thrilled to announce that DArcy was pleased ('"it was quite good...it was fine") with our midterm presentation. This was a huge victory for the Peru Structures Team which has suffered significant morale losses in previous weekly check-ins as a result of perceived poor performance. Her positive feedback will serve to bolster our team and propel us into the final stretch of the quarter. This week is a little lighter than the previous ones because we spent time reflecting and working on our mid-quarter presentations. That entails compiling what we've been working on thus far, summarizing it in 12-15 minutes (video), then making it digestible for other people in our program, and of course, readers like you. We, the Peru Structures team, were able to get a good grasp on the other ESW projects, which included a data collection system for a company in the Dominican Republic, called Zorzal, and the other being the TCHO biochar team, who have plans of testing their product in Malaysia. Both of those teams' blogs can be read on this site (Zorzal, TCHO). If it is also any interest, their mid-quarter presentations and plans can be found here for Zorzal and here for TCHO.

Our own presentation, which includes most of the work through winter quarter and and all of spring quarter, can be watched here. We give an overview of El Gran Papiazo, its purpose and use, and talk about how we will move forward with the project now that documentation is mostly finished. We plan to start shifting more into a rudimentary prototyping phase, while making final adjustments and organization on documentation where we see fit. Two of our team members have ordered materials to make parts of our design a reality. In particularly, we wanted to focus on the interaction with the support structure and cuff. Our preliminary materials list has everything we think we need, and more things will be added if our members realize that what they ordered is not enough. Also, we plan on finding new ways to 3d Print (or maybe prototype in different ways) as the company we found prior has changed their shipping times drastically, from a couple days to now over a month. The 3D print order isn't viable anymore since it would arrive in June. At this point in time we have received these materials:

- Structures Team We are almost at the end of our documentation project to help next years structures team. El Gran Papiazo's first draft is finally complete and ready for a just a few quick edits. We are hoping that with this document, next year's structures team can save a few weeks of trying to figure out the project and what works / what doesn't work and can get straight to designing and prototyping. It is the best we can do given the current Covid situation. All of our team members have also been preparing videos that should be ready soon to supplement El Gran Papiazo (Los Granes Videos perhaps?).

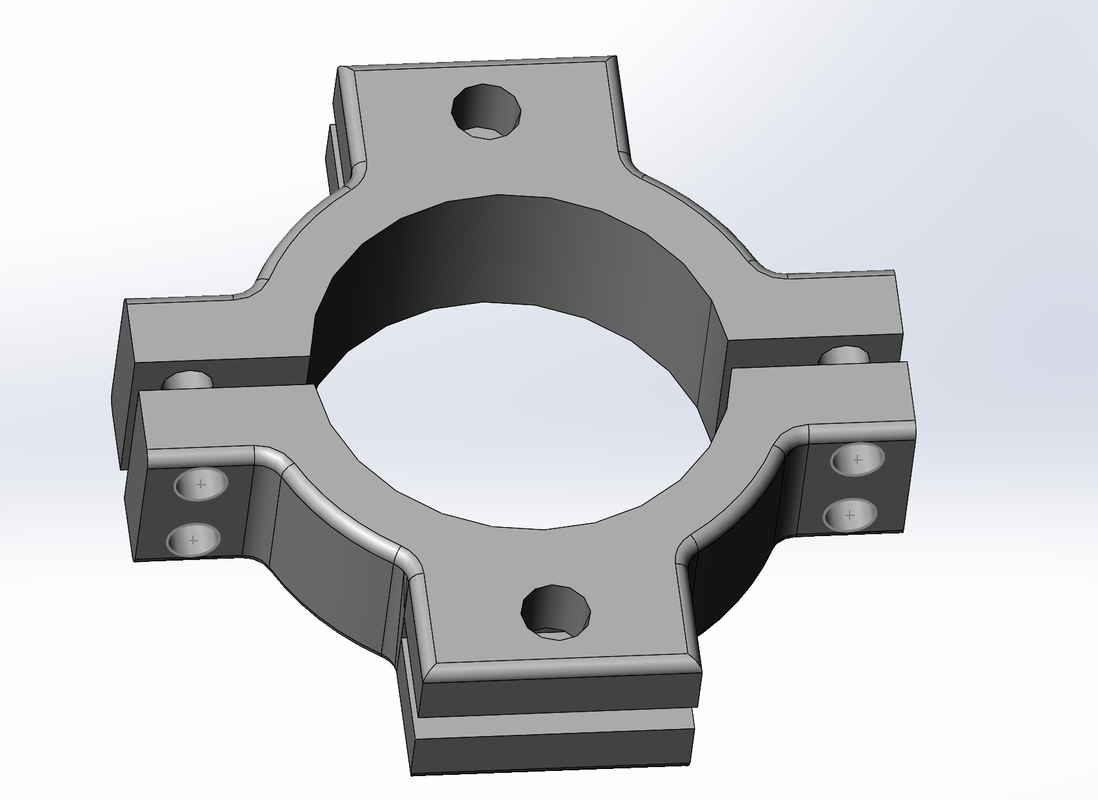

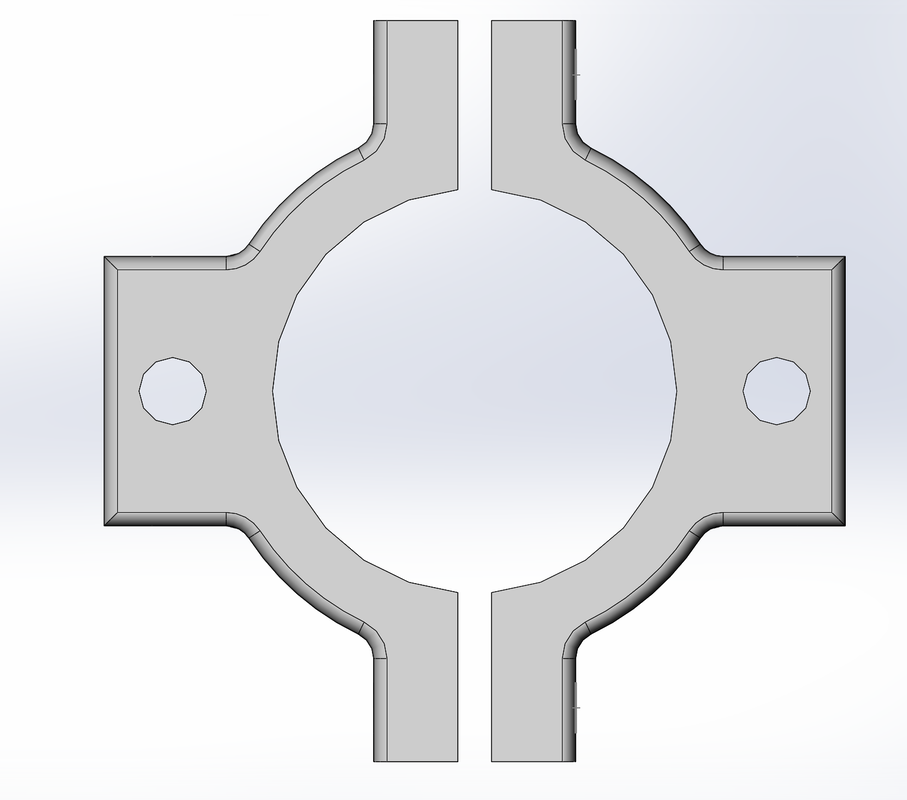

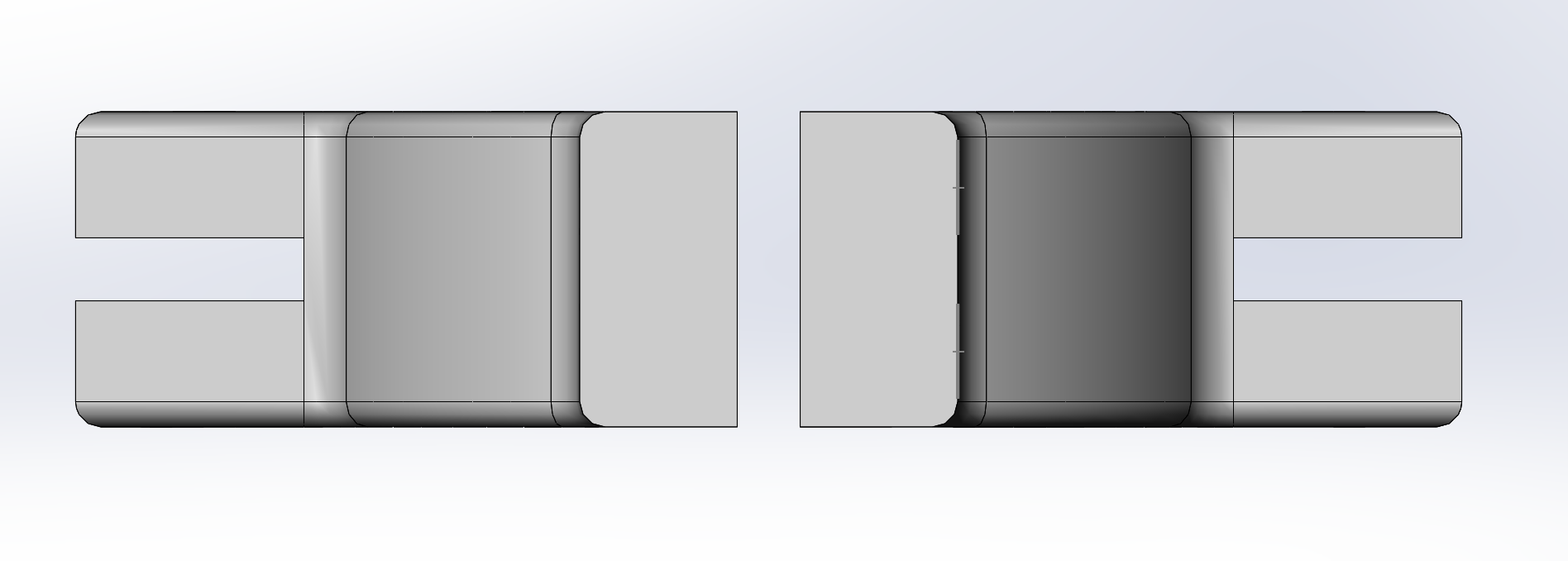

This week we also finished editing and revising last quarters project statement. We hope that now it is crystal clear. The document should now be fully robust in describing what the purpose and specifications of the roof that will eventually be built are. We also finished our bill of materials and are ready to order and ship materials to two of our team members' homes so that they can begin whatever minor quarantine prototypes they can manage. We plan on having one team member prototype the connection from the poles to the canvas. This prototype will involve a 3D-printed model of the cuff. Another team member will make a wooden prototype of the cuff and its connection to the poles. As we continue to make progress on the document we're preparing for next year's team, the document has begun has to take on some character of its own. For starters, it has been dubbed "el grab papiazo" in reference to its all-encompassing, all-powerful nature. The tradition of naming our work dates back to when we first started naming our roofing ideas. To an outsider, such antics may appear counterproductive to the mission of our team to deliver high-quality, thoughtful work grounded in engineering principles. In our view, however, this perception is flawed. As we see it, you name the things you care about. We care about our work and the names are symptomatic of this passion.

Furthermore, there is some practical value to our team's antics. One of the learning challenges in preparing this document has been understanding the difference between writing for technical documentation and writing to tell a story. Next year's team will have access to all of our technical documentation. The purpose of el gran papiazo, however, is to tell a story that Peru Structures team 2021 can read and learn from. At times, the technical, precise nature of documentation is advantageous. However, such documentation often excludes the nuances of the process of arriving at the technical figures in order to preserve concision and clarity. Though el gran papiazo is on the longer side, we hope that it will prove to be readable and nuanced in order to fill in the gaps inherent in our technical documentation. In the spirit of this nuance, in the last week, we made significant progress increasing the readability of our document. By opting for less-technical word choice, reformatting our sections to include easy-to-read charts and tables, and including personal anecdotes, we hope to provide the sort of mix of facts and nuance offered by a knowledgeable mentor. We still have work to do reformatting the end of the document and including transitions to avoid making any assumptions that might confuse next year's team. Already, though, writing el gran papiazo has been a fun and useful exercise in technical communication (and creativity - checkout the life advice in the form of Haikus). The last week was spent diving into our documentation. We adjusted our main outline to include a background of the project and site, what ideas worked both last year and this year, and what ideas have not worked. Per Latifah’s recommendation, we aim to provide next year’s team as thorough a body of information as possible. Below are a few of the aspects we have focused on to ease the project familiarity process for the 2021 team.

By providing an overview of the tools and materials available at Chavin, Huaraz, and Lima, we’ll hopefully leave next year’s team better prepared to accurately plan how and where they will source all their materials. Additionally, both the 2019 and 2020 teams have come up with an extensive list of technical requirements. Aware that many of these specifications include project-specific terms, we define key terms such as “modularity,” “water permeability,” and “reversibility,” which define the overarching goals of our project. Defining these terms was important in terms of creating specific technical specifications that a team can test against through experimentation. Another relevant section we have created covers things one might think would work but actually wouldn’t. These were ideas, such as ordering various large parts online, we had spent some time discussing before ultimately realizing they weren’t feasible. We hope these explanations will save the 2021 team time and allow them to get started revising requirements and prototyping as quickly as possible. Our next steps for this week are to continue synthesizing information from previous documents, compile a video summarizing the entire document and especially our prototypes, and further sharpen the document to be concise and easy-to-read. Well, this quarter's not starting out in the most ideal of situations. With COVID19 running rampant and all of our team members sent home, you might be asking how we will continue our project. We asked ourselves the same thing. But, refusing to produce nothing, we've come up with a game plan this coming quarter to ensure some progress, albeit less than expected, in the project. It's true we don't have the necessary materials/tools to make a robust prototype and do excessive failure testing, but there is still some room to make some prototype. That part is for a little later though. First we'll explain how this quarter is roughly planned out!

Reflecting on something we could do remotely, we immediately thought of the documentation, which all lives in online files. Well, what about documentation? Further introspecting, we remembered how difficult it was for us to sift through all the material(s) of previous years to find relevant info. Data on what worked, and what didn't was all there, but the process to find it was very roundabout. Thus, our first, remote goal of this quarter is to create a streamlined document, a guide/crash course, for next year's team to ensure smooth handoff of the project. So the hours spent looking for information like technical specs can better be used designing and making prototypes, something we fell behind on in winter. To reduce the density of our guide, we resolved to film some short segments, because a video is more engaging than reading blocks of text. Our outline of the guide is here: shorturl.at/myIW2 We plan to have that documentation completed by the midterm mark, so we can quickly switch our focus to available prototypes and testing. Some team members have hand and power tools and thus can possibly make wooden prototypes. Mainly, we will outsource one prototype to a 3D printer vendor. Regardless, we have a new, working Bill of Materials. Though we are all apart, there is still hope to come up with some project! The second half of the quarter will ideally be solely focused on this build and test. Any interesting results we find will surely be added to the guide. That's all for now. In these trying times, we're glad to have found a way to forge ahead with our project. Every little difference counts, and if that means we're simply passing the baton to the next team, then so be it. We'll continue proudly! - Structures Team If last update was all about large scale planning and looking at the overall roof design, this week's update is more about focused design. For this section of winter quarter we really zoomed in on a specific critical part of our tensile roofing structure: the cuff. For some context, the cuff is the mechanism/piece that attaches to the supports AKA eucalyptus poles of the structure. You can reference Update 1 to get a clearer picture.

With the cuff, we spent some time looking at last year's designs in Solidworks. Things like checking out the features, examining the sketches, and double checking various dimensions. Once we had a good grasp of what we were working with, we thought up of some ways we could improve the design so that it would interact nicely with an angled, flat roof. We came up with adding a vertical component in which we could drive a screw through, and that would hold the canvas that is grommeted (see diagrams below). We used time to iterate and make new SW files. This week, we will be 3D printing and fast prototyping (i.e. wood) different versions of the new cuff. Hopefully this will give us insight on assembly and allow us to run some quick tests. Now that we have the files, we can also apply FEA once we figure out where the most stress would be applied. Regardless, the direction we are moving currently is perfecting a cuff design given our new slanted structure. Other things that occurred since the last update include: a second meeting with Professor John Rick, who helped us further develop ideas on drainage and modularity; editing some of our documentation (i.e. risks, BoM, Timeline); discussing how we will test our critical part/overall structure. As we move from design to manufacturing/prototyping we are running into challenges on how we will test things. We are currently unsure how to tests different loads, weather conditions, and so on. One of our requirements is also longevity, but we do not have a solid idea on how to simulate a year's worth of conditions on our models. Also scale is important, and how we can apply results from small models to the real, big thing. We are working towards it all though, slowly but surely! - Structures Team We're back! Over these three weeks we've been iterating, designing, and discussing on some courses of action to take with our project. In the last update we talked about: making the decision to continue with last year's tensile roofing project and discussions with Civil Engineering Professor Sarah Billington to come up with some overarching guidelines/structural themes. This update is more focused on the type of tensile roofing we want to make.

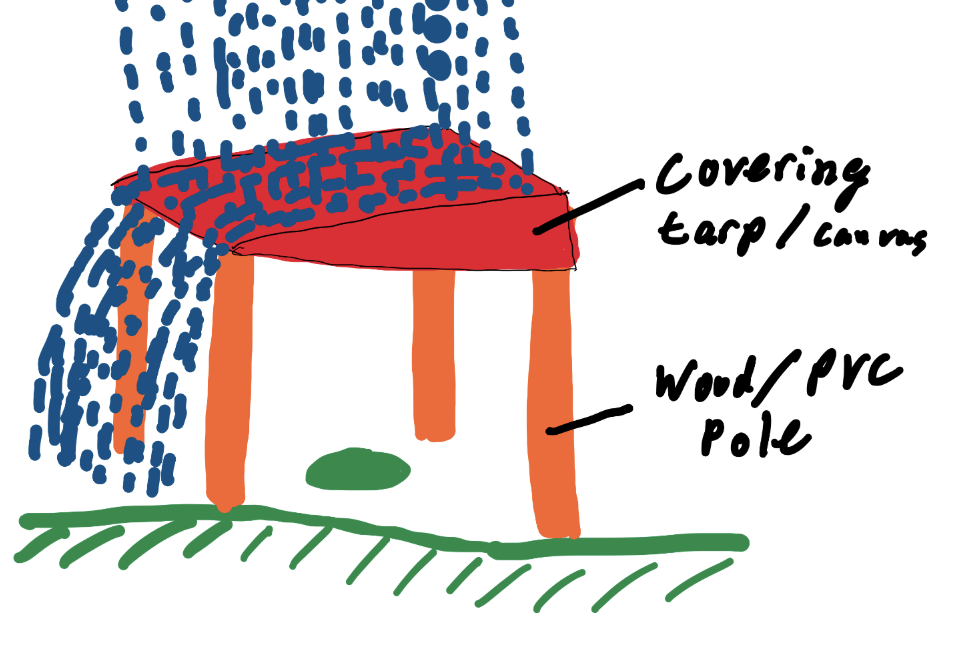

From the previous year, we identified some issues with the domed roofing (see last update for reference/pictures). One was that drainage was difficult to handle, since water was dispersed evenly on all sides. We posited that a flat, but slightly angled roof would direct rainfall in one direction, thus making it easier to deal with. On the one drained side, we played around with the idea of PVC people guttering, but that is not completely fleshed out yet. This would also help with the molding that the roofing structures would experience. Another helpful part of slanted roofing, was its build would be much less complex than a dome, which required bending rebar and drilling some inconvenient holes to get the "curve" just right and stable. This directly leads into meeting some specifications we set in regards to construction/deconstruction time and reversibility. Simpler geometry makes both those requirements faster and easier. Finally, a slanted roof could be aesthetically pleasing in the modular sense. From certain angles on the ground they could almost be "invisible" while also letting in a decent amount of sunlight in under the structure due to one side being higher than the other. Regardless, this change could lead to some good things for the tensile roofing project, and we will move forward with this, attempting to model a smaller version in the future. See below for a quick sketch of the new design. Admittedly, we are still facing issues of keeping the roof truly tense. Regardless of how we clamp it, there will be dips as the material(s) stretch over time. Talks with Professor John Rick in the future may reveal better methods of minimizing dips as much as possible. Possible having lightweight beams run along the distance could be a good solution, though we have not come up with what those beams would be made out of, since too heavy could overload the structure. More challenges with this project include trying to fit our severe lack of materials and tools to the many (7+) user requirements we set for ourselves. Upon finishing a mid-quarter presentation and review, we realized that maybe some goals can go in favor of focusing on others. Those include things like longevity (make it last for 2+ years) and large scaleability (have 10 combined to cover a huge site). We are still deciding, but the scope of our project is definitely looking like it could change. - Structures Team Hey everyone! With week four of our winter quarter almost underway, now is a perfect time for a quick update on what the team is up to. We have spend a considerable amount of time planning before we jump into intensive design and implementation. The majority of the past couple of weeks has been spent meeting with prior Structures team members (most notably last year's team lead Joanna Liu), current Stanford professors, and archeological liaison Professor John Rick. All these meetings have given us insight on the direction the project has been going and most importantly the constraints and goals of the structures we are designing. Things like materials, weather, and tools were made much more clear to us after repeated meetings and research.

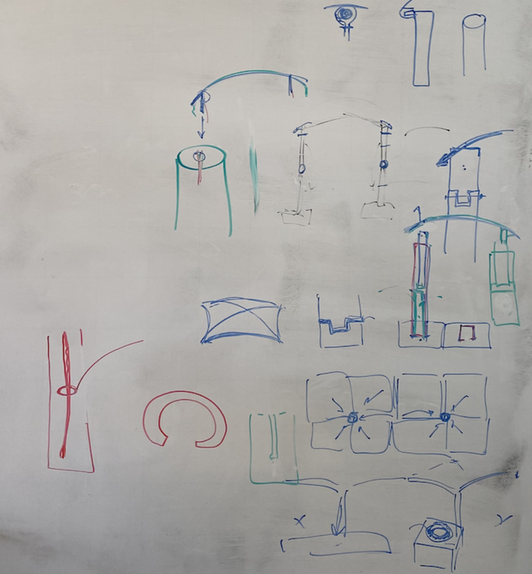

Initially we were split between two types of projects: stabilization and roofing. The latter is what the prior Structures team worked on. They designed a simple version of tensile roofing (see below), which revolved around a cuff design. We spent some time mulling over the idea of iterating on this or completely starting new. We decided it was best to build on their momentum and continue down the roofing path, though not necessarily with the cuff design since that came with its own obstacles. Some of those included lack of proper tension on the canvas and vulnerability to the weather conditions. We are currently deciding between multiple designs and plans to try and find the best option to fulfill some of this year's goals: mobility, modularity, and easy water drainage. We are under constraints of reversibility, materials/tools, identifiability, and aesthetics. It is important to note though that the stabilization of tunnels/excavations is definitely a long term goal that we hope to make some progress on these two quarters. Lay the groundwork for that, even if it may be a small contribution. Another point of significance was our meeting with Civil Engineering Professor Sarah Billington, who gave us effective guidance on how we would approach designing an effective roofing structure. Together, we brainstormed some good ideas, and those rough sketches are below, to show the process we worked through. Overall, while no solid product has been decided on yet, we are happy that we've spent considerable time thinking about the overarching themes. We want to have a solid understanding of the problem before we hop into a robust solution. The foundation is built and we're on our way! - Structures Team |

AuthorWrite something about yourself. No need to be fancy, just an overview. Archives

June 2020

Categories |

RSS Feed

RSS Feed