|

If last update was all about large scale planning and looking at the overall roof design, this week's update is more about focused design. For this section of winter quarter we really zoomed in on a specific critical part of our tensile roofing structure: the cuff. For some context, the cuff is the mechanism/piece that attaches to the supports AKA eucalyptus poles of the structure. You can reference Update 1 to get a clearer picture.

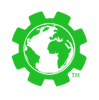

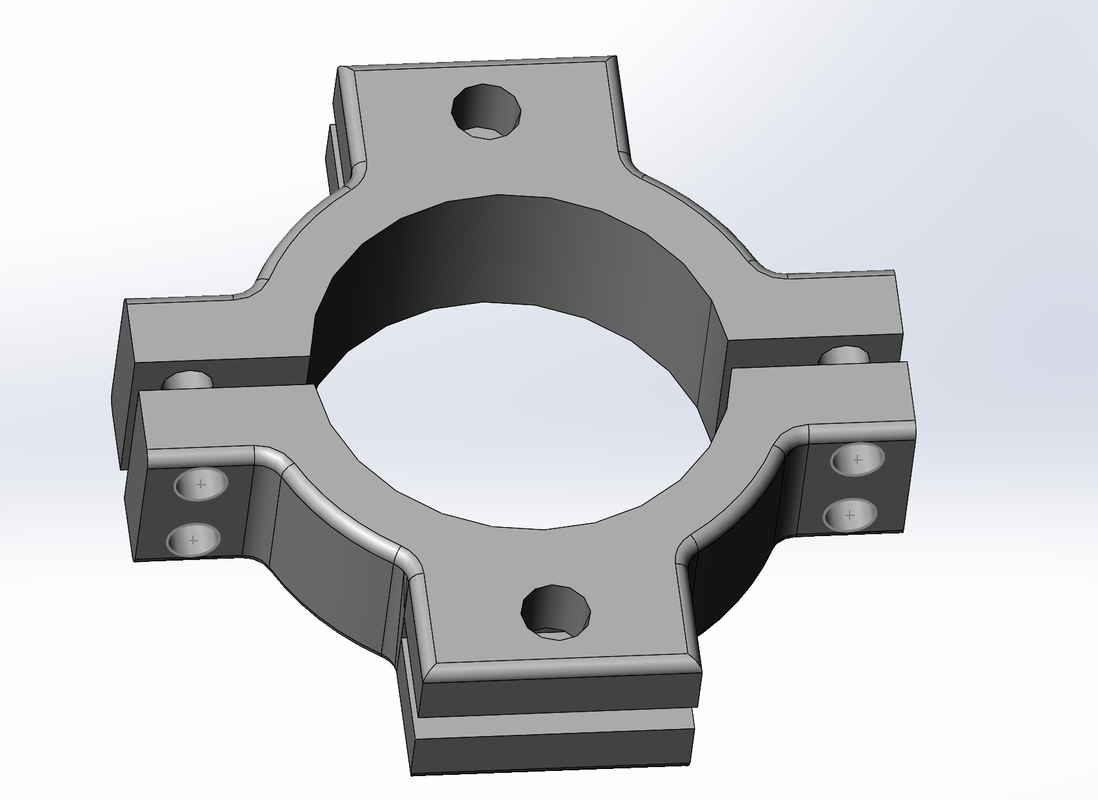

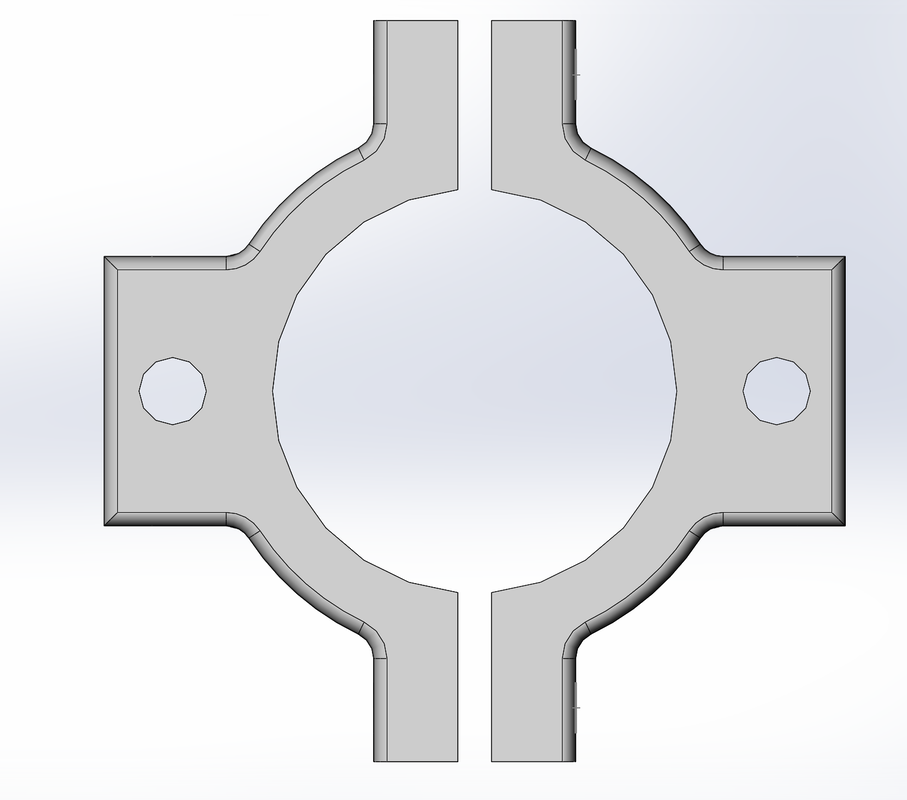

With the cuff, we spent some time looking at last year's designs in Solidworks. Things like checking out the features, examining the sketches, and double checking various dimensions. Once we had a good grasp of what we were working with, we thought up of some ways we could improve the design so that it would interact nicely with an angled, flat roof. We came up with adding a vertical component in which we could drive a screw through, and that would hold the canvas that is grommeted (see diagrams below). We used time to iterate and make new SW files. This week, we will be 3D printing and fast prototyping (i.e. wood) different versions of the new cuff. Hopefully this will give us insight on assembly and allow us to run some quick tests. Now that we have the files, we can also apply FEA once we figure out where the most stress would be applied. Regardless, the direction we are moving currently is perfecting a cuff design given our new slanted structure. Other things that occurred since the last update include: a second meeting with Professor John Rick, who helped us further develop ideas on drainage and modularity; editing some of our documentation (i.e. risks, BoM, Timeline); discussing how we will test our critical part/overall structure. As we move from design to manufacturing/prototyping we are running into challenges on how we will test things. We are currently unsure how to tests different loads, weather conditions, and so on. One of our requirements is also longevity, but we do not have a solid idea on how to simulate a year's worth of conditions on our models. Also scale is important, and how we can apply results from small models to the real, big thing. We are working towards it all though, slowly but surely! - Structures Team

0 Comments

|

AuthorWrite something about yourself. No need to be fancy, just an overview. Archives

June 2020

Categories |

RSS Feed

RSS Feed