|

We're back! Over these three weeks we've been iterating, designing, and discussing on some courses of action to take with our project. In the last update we talked about: making the decision to continue with last year's tensile roofing project and discussions with Civil Engineering Professor Sarah Billington to come up with some overarching guidelines/structural themes. This update is more focused on the type of tensile roofing we want to make.

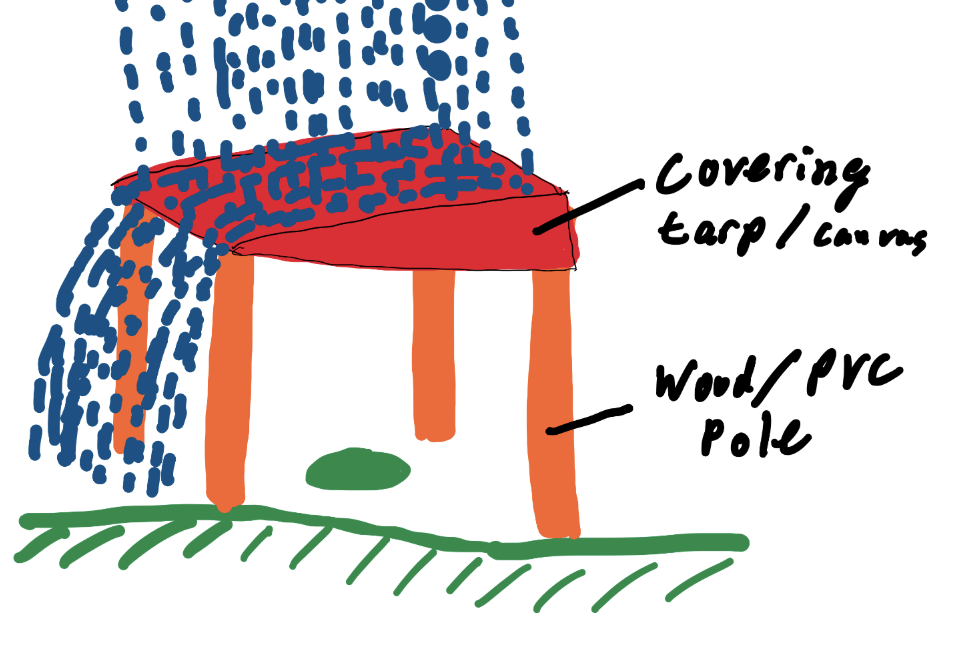

From the previous year, we identified some issues with the domed roofing (see last update for reference/pictures). One was that drainage was difficult to handle, since water was dispersed evenly on all sides. We posited that a flat, but slightly angled roof would direct rainfall in one direction, thus making it easier to deal with. On the one drained side, we played around with the idea of PVC people guttering, but that is not completely fleshed out yet. This would also help with the molding that the roofing structures would experience. Another helpful part of slanted roofing, was its build would be much less complex than a dome, which required bending rebar and drilling some inconvenient holes to get the "curve" just right and stable. This directly leads into meeting some specifications we set in regards to construction/deconstruction time and reversibility. Simpler geometry makes both those requirements faster and easier. Finally, a slanted roof could be aesthetically pleasing in the modular sense. From certain angles on the ground they could almost be "invisible" while also letting in a decent amount of sunlight in under the structure due to one side being higher than the other. Regardless, this change could lead to some good things for the tensile roofing project, and we will move forward with this, attempting to model a smaller version in the future. See below for a quick sketch of the new design. Admittedly, we are still facing issues of keeping the roof truly tense. Regardless of how we clamp it, there will be dips as the material(s) stretch over time. Talks with Professor John Rick in the future may reveal better methods of minimizing dips as much as possible. Possible having lightweight beams run along the distance could be a good solution, though we have not come up with what those beams would be made out of, since too heavy could overload the structure. More challenges with this project include trying to fit our severe lack of materials and tools to the many (7+) user requirements we set for ourselves. Upon finishing a mid-quarter presentation and review, we realized that maybe some goals can go in favor of focusing on others. Those include things like longevity (make it last for 2+ years) and large scaleability (have 10 combined to cover a huge site). We are still deciding, but the scope of our project is definitely looking like it could change. - Structures Team

0 Comments

|

AuthorWrite something about yourself. No need to be fancy, just an overview. Archives

June 2020

Categories |

RSS Feed

RSS Feed