|

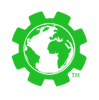

Having detailed our prototype and operations in the previous two blogs, we will provide a testing update this week! For easy access, our procedure for building our prototype can be found in this previous blog post and in this video. The clam chowder can mentioned in the previous blog was the perfect fit for our inner chamber as it created an airtight seal when placed inside the larger paint can. After finishing the drilling, we were able to complete our first prototype! Pictures of the completed prototype. Things to note: the sealed fit between the two inner cans and that the bottom of the inner can will not touch the ground (allowing airflow through the bottom holes). Last Thursday, we completed a preliminary test of our small-scale TLUD biochar kiln. Initially, we hoped to use the "husks'' that we received through a donation in the winter. However, based on their appearance and chocolatey aroma, we suspected that the organization sent us the husks of the cocoa beans and not the pods. The initial attempt confirmed our suspicions, as the bean husks failed to ignite. As a result, we pivoted to wood chips, sticks, and leaves as feedstock, collecting them from around the PRL courtyard area. Here is a brief recap of our results, observations, and key takeaways! It was a huge moment of growth and learning for our team.

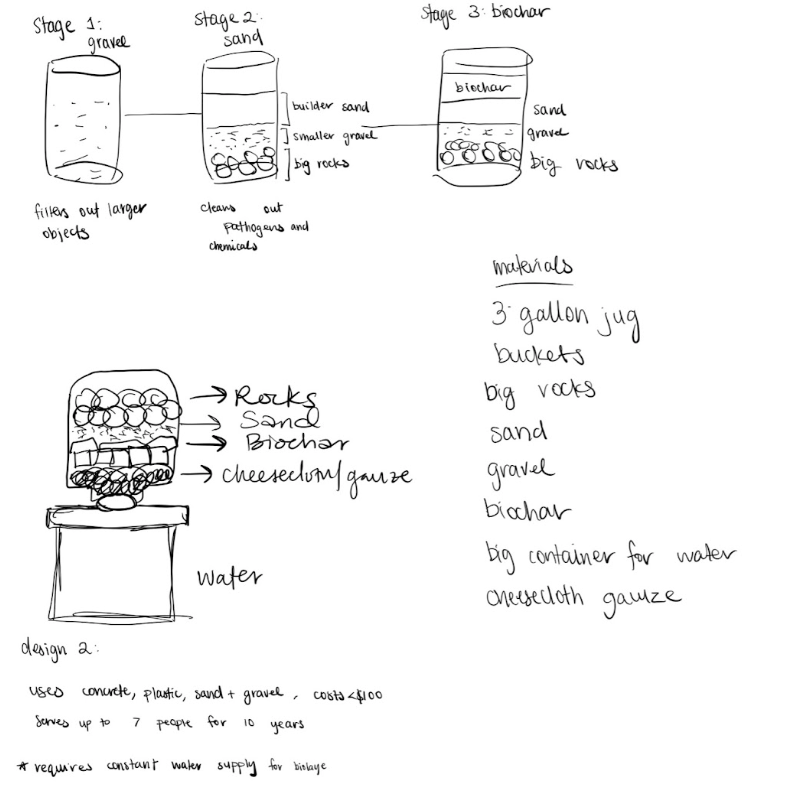

The sequence of our first burn! First picture shows us lighting the feedstock with a match, with a high density of dry leaves at the top to ensure the feedstock catches. Second picture shows the fire in action, and the third picture shows the final product. Next Steps on our Sand Filter: The team has identified two potential designs for our sand filter. Below are sketches of what we are envisioning: The first design utilizes three different buckets, one with gravel, one with sand, and one with sand, gravel and biochar. We have made a plan to acquire materials and hope to make a trip to Home Depot by the time this blog is submitted. We will also consult with teaching team member Emily Wong since she worked on a similar filtration mechanism last year.

0 Comments

Leave a Reply. |

AuthorWrite something about yourself. No need to be fancy, just an overview. ArchivesCategories |

RSS Feed

RSS Feed