|

Last week, we met as a group to discuss and update our direction, goals, and individual responsibilities. We are feeling purposeful and energized as we head into the last six weeks of the quarter (how time flies!). In their weekly meeting, Isabelle and Ananya received exciting news from Ayisha – a member of our Biochar team who is currently working remotely (we miss you!). Ayisha successfully met with two potential partners on the Malawi side – Pam Haigh, a General Manager at Ripple Africa, an established organization that aims to empower Malawian communities toward a sustainable future – and Rodger Makwinja – a groundwater and quality researcher from the Addis Ababa University who has worked on the ground in southern Malawi. Haigh expressed interest in our work, offering to host us in the future and support and collaborate with our biochar production and water filtration efforts. Makwinja provided useful insights about community attitudes and preferences as well as the importance of a preliminary, exploration-based survey. Based on this information, we decided to simultaneously focus on testing the biochar kiln, building and evaluating the water filter, and conducting more contextual research about Malawi while reaching out to stakeholders. We divided our group into 3 sub-teams in order to streamline work and accomplish our goals efficiently. The biochar production group (Julia and Sebastian) will test the kiln with various feedstocks (husks – the wastestream in Ghana – and corn – that in Malawi) as well as different shapes and sizes of these inputs. They will document results using our newly-purchased scientific instruments as well as observation. The water filter group (Nomunzul and Bryana) will first construct the filters (as referenced in the last blog)with the acquired materials. On this note, another milestone last week was acquiring all the necessary materials for our sand filter from Home Depot. After a successful trip, we found storage for our materials and can begin prototyping the filter in the PRL over the next few weeks. Once built, the filters will be tested with local creek water, known to be contaminated with E. coli. We plan to use water tests like the Colilert kit to see how effective our filters are. Lastly, the research group (Isabelle and Ananya) will continue to develop a clear picture of the reality in Malawi as well as the different partners in the area. We hope to create a draft of a User Study by the end of the quarter that will address important concepts such as distance to available water and daily schedule, which will inform our designs and conceptualization of potential solutions. Many group members are motivated to travel to Malawi at the end of the summer; we are currently looking into the opportunity as well as sources of funding. And, lastly, next week, we plan to meet with Johannes Lehmann – a soil fertility and biogeochemistry professor, well-versed in the research and use of biochar – to discuss basic methods to assess the quality of the biochar that we produce in our kiln. Overall, we are excited to be working on this project with a newfound sense of direction and local connections that will help us build a useful and meaningful product.

Pictures of the team at home depot >.<

0 Comments

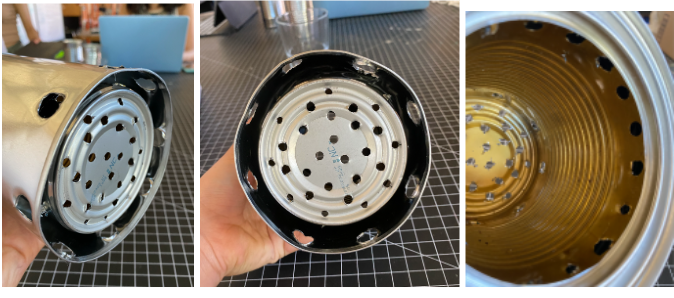

Having detailed our prototype and operations in the previous two blogs, we will provide a testing update this week! For easy access, our procedure for building our prototype can be found in this previous blog post and in this video. The clam chowder can mentioned in the previous blog was the perfect fit for our inner chamber as it created an airtight seal when placed inside the larger paint can. After finishing the drilling, we were able to complete our first prototype! Pictures of the completed prototype. Things to note: the sealed fit between the two inner cans and that the bottom of the inner can will not touch the ground (allowing airflow through the bottom holes). Last Thursday, we completed a preliminary test of our small-scale TLUD biochar kiln. Initially, we hoped to use the "husks'' that we received through a donation in the winter. However, based on their appearance and chocolatey aroma, we suspected that the organization sent us the husks of the cocoa beans and not the pods. The initial attempt confirmed our suspicions, as the bean husks failed to ignite. As a result, we pivoted to wood chips, sticks, and leaves as feedstock, collecting them from around the PRL courtyard area. Here is a brief recap of our results, observations, and key takeaways! It was a huge moment of growth and learning for our team.

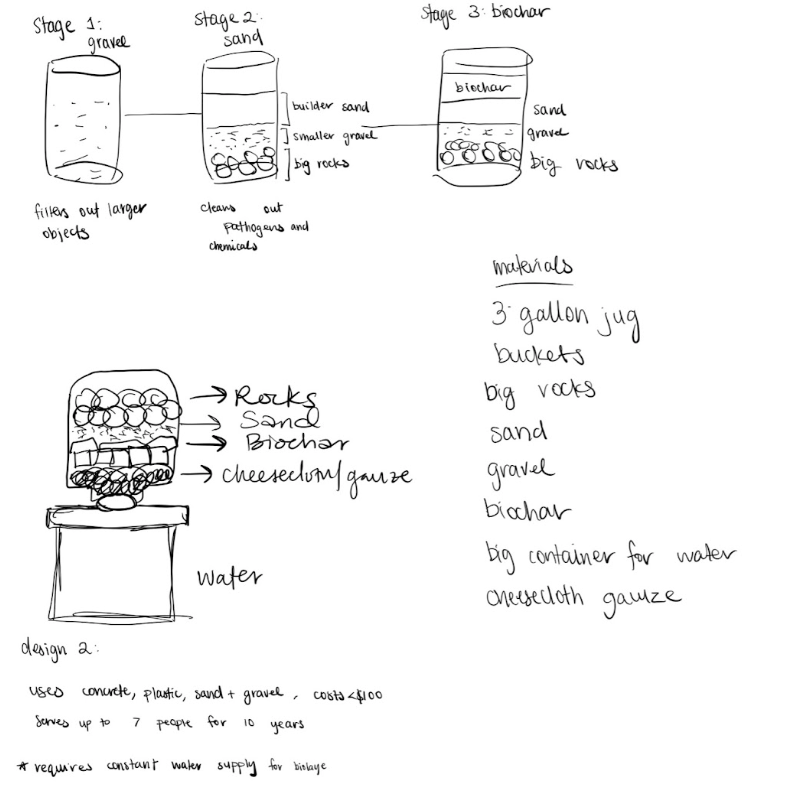

The sequence of our first burn! First picture shows us lighting the feedstock with a match, with a high density of dry leaves at the top to ensure the feedstock catches. Second picture shows the fire in action, and the third picture shows the final product. Next Steps on our Sand Filter: The team has identified two potential designs for our sand filter. Below are sketches of what we are envisioning: The first design utilizes three different buckets, one with gravel, one with sand, and one with sand, gravel and biochar. We have made a plan to acquire materials and hope to make a trip to Home Depot by the time this blog is submitted. We will also consult with teaching team member Emily Wong since she worked on a similar filtration mechanism last year.

Biochar 2022 Team: Nomunzul, Isabelle, Ananya, Bryana, Sebastian, Ayisha, Julia Picking up from where we left off in winter quarter, the 2022 Biochar Team is eager to continue prototyping our biochar kiln and begin the prototyping process for our water filtration system! Connecting to our last blog post, our current kiln design is a small-scale prototype of a TLUD (Top-lit Updraft gasifier) made with a paint can, soup can, and tuna can. Last week, we reached a small roadblock, realizing that the dimensions of our soup can did not align with those of the paint can. This left a gap between the two cans, impacting the air flow. After hunting through local grocery stores, we believe that we have located the perfect candidate for our project: a Progresso Clam Chowder can from Stanford's very own Munger Market. Now, we are drilling the last few holes in our prototype (more detailed instructions here) at the PRL. Through this initial design, our team hopes to meet the critical user requirement of making safe-to-use biochar – not charcoal. After burn tests, we will test the output to assess the effectiveness of our prototype based on the quality of biochar produced, looking into the chemical composition of the biochar as well as its toxicity. A subset of our cohort is currently researching available testing kits for this step. Following a successful testing phase, our team anticipates scaling up (given positive test results) and focusing on ways to locally-source required materials for our partner communities in Ghana and Malawi. Furthermore, for the water filtration system, our team will use the biochar produced from our kiln or biochar that we purchase to develop the sand filter design. Through this, our team hopes to build cohesion between the Ghana and Malawi sides of our project by working on both simultaneously and consistently discussing the ways our partner organizations are both similar and different. Such conversations may affect the kiln and water filtration prototypes. By the end of the quarter, our team aims to build and design a large-scale biochar kiln and prototype a few filtration systems that possess the ability to produce safe drinking water.

|

AuthorWrite something about yourself. No need to be fancy, just an overview. ArchivesCategories |

RSS Feed

RSS Feed