|

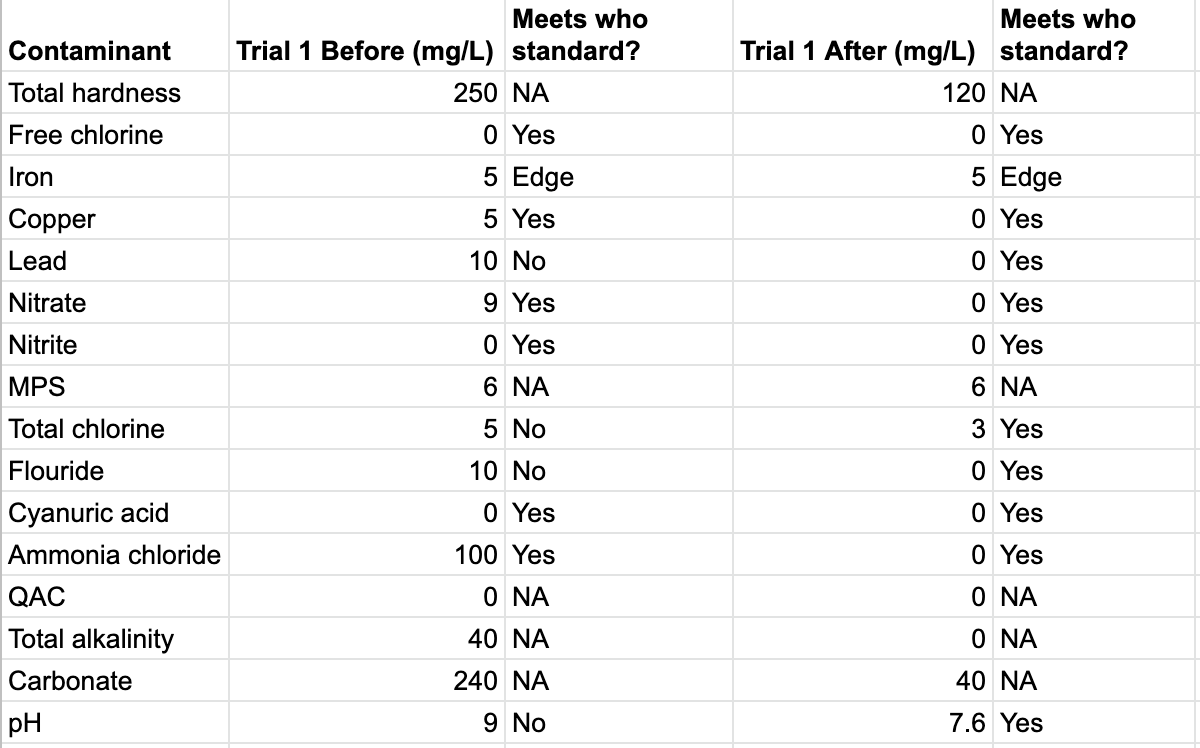

We are so excited to share the preliminary results of our water testing. Using the water from San Francisquito Creek, we found that – before filtration – the water did not meet WHO standards in the following categories: iron, lead, total chlorine, fluoride, and pH. Interestingly, it did not possess any E. coli bacteria (as indicated by a negative test result) – something that we had been expecting and hoping to test the effectiveness of our filter on. This could be due to the way that we stored the water, the questionable quality of the test itself, the fact that the test blew over during the incubation period, or misinformation about E. coli levels in the creek. After the filtering process which took approximately 45 minutes, we retested the water and were pleased to find that our design dramatically improved the water quality. More specifically, it reduced the levels of all contaminants, bringing them within the range of WHO standards and thus making it drinkable with regard to these metrics. So awesome! With the promising results, we want to continue our designs and testing in a few different ways. First, a sub-group of the team has turned their attention to the second filter prototype – the single-bucket gravity filter – and are beginning the construction phase today. Additionally, we want to test the first design with a more robust and credible test, such as the IDEXX ones described in an earlier blog. And lastly, in an effort to learn more about our filtration system's ability to remove bacteria, we are retesting the filter with new, more legitimate bacteria tests. We also plan to refrigerate our next batch of creek water – a step that will contribute to the health of the E. coli population. It seems weird to be promoting this type of growth but it is in the name of the safety of our users! On the kiln side, we started sourcing materials for a larger, full-scale TLUD kiln. Our initial focus is the oil drum. We have found some options on Craigslist and Facebook Marketplace and are working on selecting the best drum – considering costs, presence or absence of paint, and distance from Stanford. We understand that our team may not finish building this design. Instead, we aim to set up the next ESW Biochar team for success!

0 Comments

Last week was huge for us! On the kiln front, we successfully created biochar from the cocoa husks. Not only did this feedstock light, it also resulted in % yield. We believe that the change in flammability stems from the husks having spent more time drier since they arrived from Ecuador, our team members learning how to block the wind and more effectively use the lighter, and Latifah provided critical advice on how to construct a tent of kindling around the husks. Moving forward, we plan to further test our kiln by continuing to burn both maize and cocoa husks and aiming to achieve 80% yield in at least three trials for each.

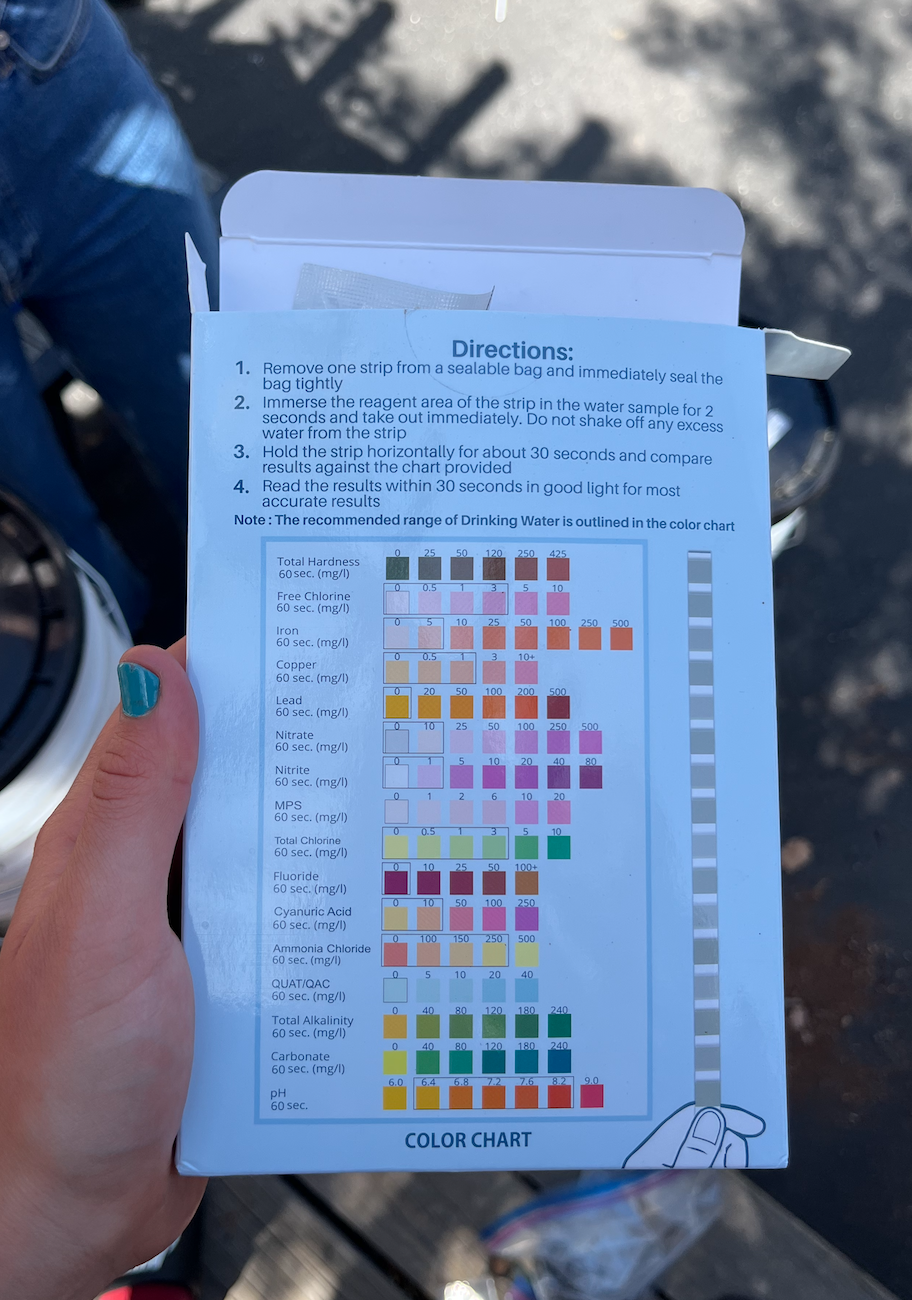

Moving to the water filter, we Zipcared to ACE Hardware to acquire a bucket and then headed off to the nearby Francisquito Creek – which is known to be contaminated by E. coli among other contaminants. After scaling a steep bank and rinsing the bucket multiple times as was recommended by a Stanford professor who focuses on water quality, we filled our bucket with creek water and transported it back to our workspace. Beginning today, we plan to work to eliminate the leakage in our filter system by connecting the holes between buckets with a Ziploc funnel that does not allow water to exit the system. Once implemented, we will test the creek water for E. coli and heavy metals prior to filtration and record results. For testing, we have purchased WaterSafe Bacteria Test Strips and an SJ-Wave Water Test Kit. Next, we will allow the water to pass through the filter and retest and re-record the E. coli and heavy metal readings. In order to gain insights on the filter's effectiveness, we will compare the readings. From there, we will likely iterate and repeat until our design removes contaminants and ensures that the water is in compliance with WHO water standards and that E. coli and chloroform levels are zero. If results are promising, we will invest more in certified water tests, such as those listed in our Bill of Materials – which includes the IDEXX Colilert test, IDEXX, Enterolert-E test, and Arsenic Low Range test. The water testing centers around the user and technical requirements of conformance to health standards. Drinking water is critical to human health, and thus our responsibility as engineers of this filtration system is at an all-time high. We must prioritize the well-being of potential users by testing rigorously. husks to char – using the tent set up, drier 79% yield – 3 times Hi again! In preparing for our Midterm Review presentation and prototype demo day last week, we took the time to reflect on our progress thus far. We are proud of our work over the past five weeks and see potential in both our biochar kiln and biochar-sand filter designs. At the moment, each possesses its own unique strengths and weaknesses. Going forward, we hope to capitalize on the former, while addressing the latter. Additionally, we plan to move into the test phase with our water filter, continue outreach to potential new partners, and begin to think of how we will provide guidance to next year's cohort. Let's start with the kiln! We love our little paint-can stove. It has held up quite well after five burns, in which the temperature surpasses 300 degrees C. On top of this durability, it meets our other key user requirements of affordability, locally-sourced materials, and energy independence. More specifically, the fact that it is made from cans, requires minimal development work, and does not need lighter fluid or other means to start are key, facilitating our mission. Additionally, the small-scale nature allows us to iterate constantly, testing new theories about burn times, changing the type or form of feedstock, and gaining new insights each day. On the contrary, our prototype is not realistic, as its yield is minimal; a community would require a larger design in order to meet their needs and enhance their quality of life – whether it be in the form of soil amendment or water filtration. We must scale up to reach our user requirement of quantity. Further, we hope to implement Latifah's advice and successfully burn the cocoa husks – another current weakness – as we are struggling to effectively harness the wastestream. Next up, the water filter! Last week, we finished constructing our first water filtration design. Its strength lie in its ease of construction – it only took us two classes! – and the affordability of the buckets. According to our research, in Malawi, one 20 L bucket costs the equivalent of two cartons of eggs. Going forward, we plan to focus on the leaking that we witnessed in our first trial run. We will acquire and add PVC pipes to the prototype. This, along with the use of cheesecloth, presents an issue, as the materials may not be accessible in the community. Thus, we will do more contextual research on the topic and potential adjust materials. Additionally, we need to test the water filter rigorously and scientifically to protect human health and demonstrate the utility of the design. Lastly, we want to provide a recap on our filter's preliminary performance. Talking to former team members who advised that biochar often turns water black when it runs through it in a filter, however our water came out clear. While not a super scientific result, it is anecdotal promising that our water isn’t coming out looking super dirty. We are going to spend the next week working on a more rigorous testing plan and are contacting professors on campus as we speak to see if we can use their labs for water testing. Further, we are doing more research on lakeside communities in Central Malawi to determine what kind of contaminants we need to focus on removing. This will center our work and propel us in the right direction! Enjoy the photos from the past two weeks ~ biochar in pics! |

AuthorWrite something about yourself. No need to be fancy, just an overview. ArchivesCategories |

RSS Feed

RSS Feed