|

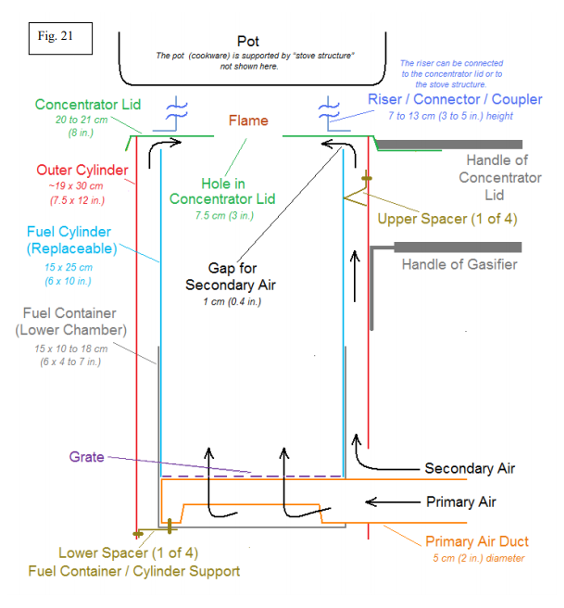

After a half a quarter of planning and research, the TCHO team is finally starting to put together our design! The past few weeks, we have developed our project and methodology, and have come up with potential designs and design alternatives. Initially, our main apparatus focused on a single compartment TLUD the size of a paint can. Upon further research, however, we preferred the pressurization from a dual component TLUD. The main drawback of the latter is that we would have to weld—a skill the majority of the team is not yet comfortable with. Moreover, for either of these options, we would need to limit emissions from the can itself, and since we are using old food cans of variable, and often times unknown, composition, this posits a significant concern for the team; these old cans may also not be able to withstand the high temperatures and pressures we hope to achieve.

Beyond a design, last week we presented the pitch for our project, enumerated a week by week plan (Gantt chart), and identified risks. Most realistically, we are concerned with the development and construction of our project—namely the risk of going over budget or not finding materials. Furthermore, we have finally scheduled our second partner call with Brad, the chief chocolate maker at TCHO. Scheduling has been difficult, nonetheless, after many failed email attempts and missed connections; but we are hopeful that Brad will put us in contact with CRIG and community partners in Ghana. Considering the many conversations we’ve had in class about ethical community involvement, we are hesitant to move forward in our project without input from the groups of people we hope to potentially benefit.

0 Comments

Leave a Reply. |

AuthorWrite something about yourself. No need to be fancy, just an overview. Archives

May 2020

Categories |

RSS Feed

RSS Feed